Summary:

[Introduction to Low Lead Certification] The low lead certification in the United States, California AB1953 certification, is a pioneer in this field. California Bill AB1953 is a legislative certification approved by the California government on September 20, 2006, which adjusted the low lead standards for products related to drinking water supply systems. This law officially came into effect on January 1, 2014. In addition to the aforementioned AB1953 certification, various low lead regulations have been proposed by the federal government, state governments, and third-party certification bodies in the United States, with numerous certification standards, such as the federal S3874 bill (1417d certification), Vermont Act 193, Maryland HB372, Louisiana HB471, and NSF/ANSI372 certification by NSF. Products sold in California must not only meet low lead testing reports but also require a third-party organization to issue an AB1953 lead-free certificate. [Scope of Lead-Free Certification] The scope of low lead certification applies to all pipes, fittings, plumbing accessories, and devices (such as faucets, valves, hoses) used in the delivery or distribution systems of drinking water and cooking water. [Lead-Free Certification Process] 1. Inquiry: Customers provide product information to the certification consulting company to obtain accurate certification costs. You can also call 13736130593 for quick information; 2. Contract Signing: Our company organizes the final certification fees, testing fees, and consulting fees into a quotation contract, and then signs the contract with the customer; 3. Certification introduction, confirmation of responsibilities, confirmation of application materials, provision of supplier information, sample requirements, document explanation, factory audit guidance, mock factory audit, promotion suggestions after certification, etc.; 4. Application Submission: After confirming certification information with the customer, submit the certification application; 5. Sample Production: The customer begins to produce samples and preliminary technical materials. 6. Product Testing: After the samples are completed, conduct preliminary tests and then submit them to the testing agency for testing to obtain a test report; 7. Factory Audit: Our company arranges project engineers to track the process to ensure a one-time pass of the audit and obtain the factory audit report (some states do not require a lead-free certificate; if only applying for a low lead report, this step does not apply); 8. Certificate Acquisition: Our company submits the test report and factory audit report to the certification body, passes the review, and obtains the certificate. Note: If applying for UPC or NSF certification together, only one factory audit is required. What is the definition of lead-free and how is it calculated? The definition of lead-free is regulated: the lead content in the solder and flux used in pipe products must not exceed 0.2%, and in pipe products and their fittings, the lead content in parts that come into contact with water must not exceed 0.25% according to the formula. Calculation method: For pipe products and fittings, the lead content of each water-contacting component is multiplied by the percentage of its water-contacting area to the total water-contacting area, and the sum of these products must not exceed 0.25%. In special cases, how is low lead calculated? A. When the lead-containing surface of a sample component is completely wrapped by a rigid inner lining (e.g., plastic sleeve) using permanent sealing measures to isolate it from water, the lead content of this component should be calculated using the lead content of the inner lining; B. When the water-contacting surface of a sample component has a coating, the lead content of this component should be calculated using the lead content of the base material beneath the coating; C. If the water-contacting surface of a component has undergone lead removal processes such as lead washing or surface treatment, the lead content of this component should be calculated using the lead content of the untreated bulk raw material. For information about AB1953/NSF372 lead-free certification or to obtain a certification quote, please call 13736130593 (24 hours), and we will respond to your inquiries promptly.

Introduction to Low Lead Certification

The low lead certification in the United States, California AB1953 certification, is a pioneer in this certification. California Bill AB1953 is a legislative certification approved by the California government on September 20, 2006, which adjusted the low lead standards for products related to drinking water supply systems. This law officially came into effect on January 1, 2014.

In addition to the AB1953 certification mentioned above, various low lead bills have been proposed by the federal government, state governments, and third-party certification bodies in the United States, with numerous certification standards, such as the U.S. Federal Government S3874 bill (1417d certification), Vermont Act 193, Maryland HB372, Louisiana HB471, and NSF/ANSI 372 certification by NSF. Products sold in California must not only meet low lead testing reports but also require a third-party organization to issue an AB1953 lead-free certificate.

Scope of Lead-Free Certification

The scope of low lead certification includes all pipes, fittings, plumbing accessories, and devices (such as faucets, valves, hoses) used in drinking water and cooking water delivery or distribution systems.

Lead-Free Certification Process

1. Inquiry: Customers provide certification product information to Shangdu Certification Consulting Company to obtain accurate certification costs. You can also call 13736130593 to quickly get the information you need;

2. Contract Signing: Our company will organize the final certification costs, testing fees, and consulting fees into a quotation contract, and then sign a contract with the customer;

3. Certification introduction, confirmation of division of responsibilities, confirmation of application materials, provision of supplier information, sample requirements, document explanation, factory audit guidance, simulated factory audit, promotion suggestions after obtaining certification, etc.;

4. Application Submission: After confirming certification information with the customer, submit the certification application form;

5. Sample Production: The customer begins to produce samples and preliminary technical materials.

6. Product Testing: After the sample production is completed, conduct certain preliminary tests, then submit to the testing agency for testing, and obtain the test report;

7. Factory Audit: Our company arranges project engineers to track the process to ensure a one-time pass of the audit and obtain the factory audit report (some states do not require a lead-free certificate; if only applying for a low lead report, this step does not apply);

8. Obtain Certificate: Our company submits the test report and factory audit report to the certification body, passes the audit, and obtains the certificate.

Note: If applying for UPC or NSF certification together, only one factory audit is required.

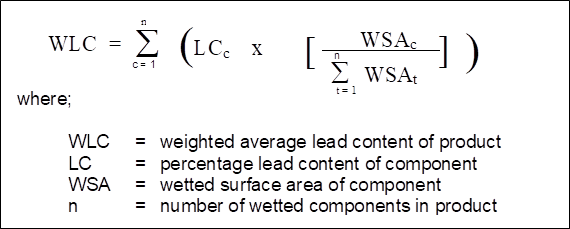

What is the definition of lead-free and how is it calculated?

- Definition of Lead-Free

According to regulations: the lead content in the solder and flux used in pipe products must not exceed 0.2%. In pipe products and their fittings, the lead content in the parts that come into contact with water must not exceed 0.25% according to the calculation formula.

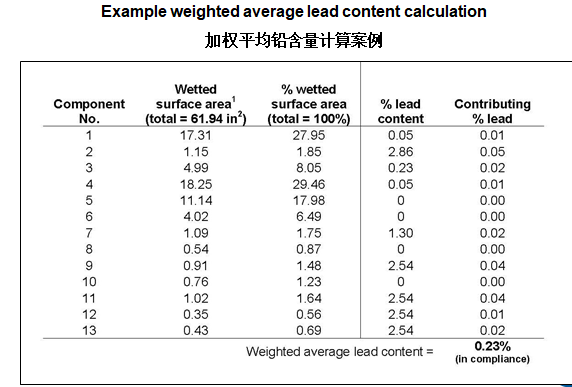

- Calculation Method

For example: for pipe products and fittings, the sum of the lead content of each water-contacting component multiplied by the percentage of its water-contacting area to the total water-contacting area must not exceed 0.25%.

- How is low lead calculated in special cases?

A. When the lead-containing surface of a sample component is completely wrapped by a rigid inner lining (e.g., plastic sleeve) using permanent sealing measures to isolate it from water, the lead content of this component should be calculated using the lead content of the inner lining.

B. When the water-contacting surface of a sample component has a coating or layer, the lead content of this component should be calculated using the lead content of the base material beneath the coating or layer.

C. If the water-contacting surface of the component has undergone lead removal processes such as lead washing or surface treatment, the lead content of this component should be calculated using the lead content of the untreated bulk raw material.

For information about AB1953/NSF372 lead-free certification or to obtain a certification quote, please call 13736130593 (24 hours), and we will respond to your questions as soon as possible.

Key words:

Plumbing and Bathroom Certification

FM Certification in the United States

EUROVENT certification

Coal safety certification

Building material certification

Eu CE certification

Other certifications

Contact Us

Address:

Room 1116, Yitian Center Building, 121 Tongji Road, Jiangbei District, Ningbo City

Other certifications