Summary:

[Introduction to KTW Certification] The German UBA (Federal Environment Agency) has established a series of UBA regulatory documents to manage products that come into contact with drinking water, ensuring they do not adversely affect human health. According to Article 17(3) of the Drinking Water Ordinance (TrinkwV2001), UBA has published evaluation criteria documents for plastics and other organic materials that come into contact with drinking water, known as KTW-BWGL. This applies to products such as plastics, organic coatings, and lubricants that come into contact with drinking water. As of March 21, 2021, KTW test certificates and W270 test certificates issued by the original laboratories will no longer be valid. For certain products, it is recommended to apply for the KTW-BWGL certificate. The new certification process includes factory audits and annual control tests as part of this new certification program. Subsequently, products such as silicone rubber and rubber will also undergo corresponding process changes. The purpose of this program is to unify European drinking water standards while strengthening the control of products related to drinking water in Germany. Therefore, in the future, only KTW and W270 tests will be recognized, and drinking water compliance certificates will be issued by organizations such as DVGW and KIWA. For updates on KTW certification, please closely follow our company's news. The KTW test focuses on whether harmful substances migrate into drinking water from products and during the production process. Testing conditions include cold water, warm water, and hot water, with test contents including TFN, TON, TOC, and some restricted substances related to formulations. [Scope of KTW Regulatory Products] Currently, products that come into contact with water are divided into four major categories, with corresponding KTW testing specifications established for each category: A. KTW-BWGL: for plastics, organic coatings, and lubricants; B. Transitional regulations for silicone rubber in contact with drinking water; C. Rubber in contact with drinking water; D. Asphalt materials in contact with drinking water. [KTW Certification Process and Cycle] A. The client submits a written application to Shangdu Company and provides accurate product information, including but not limited to product drawings, product manuals, product uses, and product characteristics; B. Confirmation of fees and certification cycle, and both parties sign a service contract; C. Formulation review (the laboratory can sign a confidentiality agreement with the client), requiring suppliers to cooperate in providing raw material formulations; D. Products in the P1 group require factory audits and sampling; E. Sample laboratory testing; F. If testing is successful, a test report and UBA certificate will be issued (as of March 21, 2021, test certificates will no longer be issued); KTW test certificate sample. Ningbo Shangdu Certification Company has rich experience in certification consulting and is committed to providing comprehensive one-stop certification services for major enterprises. If you want to learn more about this certification or obtain a certification quote, please call 13736130593, and we will respond to you as soon as possible.

The German UBA (Federal Environment Agency) has established a series of UBA regulatory documents for different materials to control products that come into contact with drinking water, ensuring they do not adversely affect human health from a hygiene perspective.

According to Article 17(3) of the Drinking Water Ordinance (TrinkwV), UBA has published the evaluation criteria document for plastics and other organic materials that come into contact with drinking water, known as KTW-BWGL. The applicable products include plastics, organic coatings, and lubricants that come into contact with drinking water. As of March 21, 2021, the original KTW test certificates and W270 test certificates issued by the original laboratory will no longer be valid. However, the test reports and test certificates for other materials or components not covered by the KTW-BWGL regulations will remain unaffected.

According to the UBA document "conformity attestation of product hygiene suitability for drinking water," non-metal components are classified into four categories (P1-P4) based on the water contact area in the final product, while metal components are classified into four categories (A-D). All components or assemblies that come into contact with water can apply for a hygiene conformity certificate. Non-metal P1 and metal A/B categories (with a water contact area greater than 10%) require factory audits and on-site sampling tests, while other categories do not require factory audits or on-site sampling. Subsequently, products such as silicone rubber and rubber will also undergo corresponding process changes. The purpose of this plan is to unify European drinking water standards while strengthening the control of drinking water-related products in Germany. Therefore, in the future, only KTW and W270 tests will be recognized, and drinking water conformity certificates will be issued by institutions such as DVGW, EUROFINS, KIWA, and HYG. Please closely follow our company's news for updates on German certification dynamics.

The KTW-BWGL test focuses on whether harmful substances migrate into drinking water from the product and its production process. The testing conditions are divided into cold water, warm water, and hot water, and the testing content includes TFN, TON, TOC, and some restricted substances related to the formulation.

[List of German Drinking Water Regulations and Related Product Scope]

Currently, products are categorized into the following major categories based on the types of products that come into contact with water, and corresponding testing specifications have been established.

A. New KTW-BWGL regulations: covering plastics, organic coatings, lubricants;

B. Standards for metal materials in contact with drinking water UBA POSITIVE LIST;

C. Transitional regulations for silicone rubber in contact with drinking water;

D. Assessment standards for elastomer materials in contact with drinking water (such as EPDM, NBR, etc.);

E. Assessment standards for thermoplastic elastomer materials in contact with drinking water (such as TPE, etc.)

F. Assessment standards for binding materials in contact with drinking water (such as cement);

G. Assessment standards for enamel and ceramic materials in contact with drinking water;

[KTW-BWGL and Hygiene Conformity Certification Process and Cycle]

A. The client submits a written application to Shangdu Company and provides accurate product information, including but not limited to product drawings, product manuals, product uses, product characteristics, etc.;

B. Confirmation of fees and certification cycle, and both parties sign a service contract;

C. Formulation review (the laboratory can sign a confidentiality agreement with the client), requiring suppliers to cooperate in providing raw material formulations, and the formulation review will be stricter and more detailed;

D. Components in P1 or metal A/B group require factory audits and on-site sampling;

E. Laboratory testing, including migration testing and EN16421 (formerly W270) microbial growth testing;

F. If testing is successful, a test report and hygiene conformity certificate will be issued (test certificates will no longer be issued after March 21, 2021);

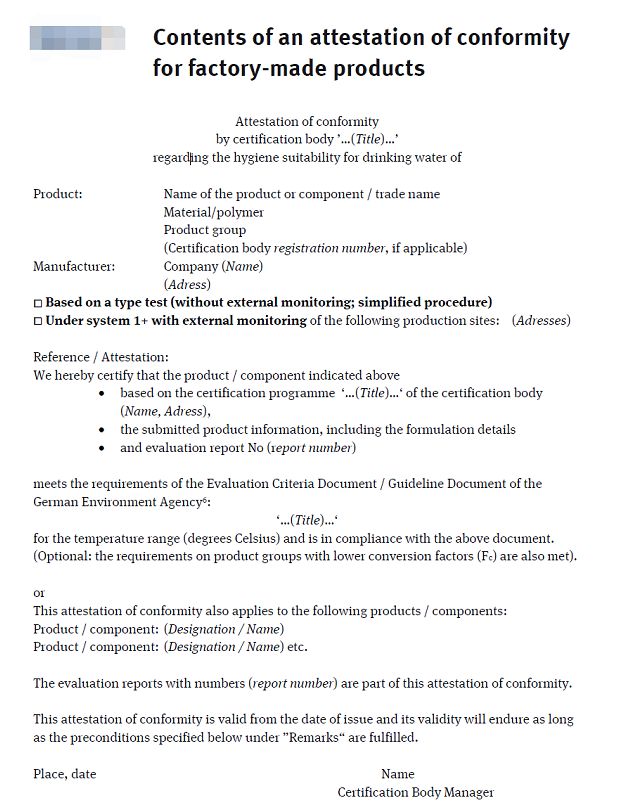

Sample of the German hygiene conformity certificate.

Key words:

KTW-BWGL

W270

DVGW

UBA

KTW

Plumbing and Bathroom Certification

FM Certification in the United States

EUROVENT certification

Coal safety certification

Building material certification

Eu CE certification

Other certifications

Contact Us

Address:

Room 1116, Yitian Center Building, 121 Tongji Road, Jiangbei District, Ningbo City

Other certifications